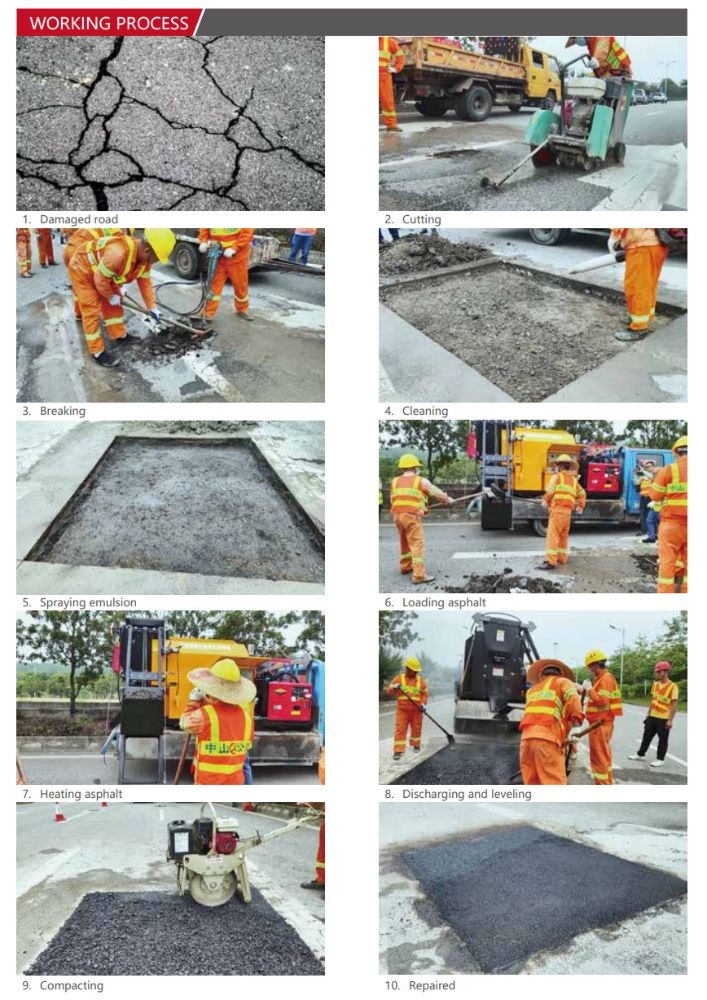

ENUO asphalt recycler is an asphalt pavement repair equipment used for mixing, heating and recycling asphalt mixture. It’s composed of drum, heating system, controller, bitumen emulsion sprayer, hot bitumen melter, engine and chassis. It’s suitable for the repair of potholes, alligator cracks, bumps, ruts, large cracks and other asphalt pavement distresses.

ENUO Asphalt Recycler offers a cost-effective, eco-friendly, and efficient solution for on-site asphalt pavement repair. Its key benefits include:

1.Time-Saving – Produces hot mix asphalt (HMA) directly at the job site, eliminating long waits at asphalt plants. The 360° rotating drum ensures uniform heating, with the first batch ready in 20 minutes and subsequent batches in just 15 minutes(up to 3 tons/hour).

2.Reliable & Versatile – Recycles 100% millings and reclaimed asphalt (RAP) into high-quality, plant-grade mix year-round. Users can customize mixes by adjusting hot bitumen content for different repair needs.

3.Cost-Effective & Eco-Friendly – On-site recycling reduces material waste and transportation costs while minimizing environmental impact. The low-consumption diesel generator (6L/hour) and high-efficiency Italian burner further lower operational costs.

4.User-Friendly Design – Features an intuitive control system for easy operation. The 100L thermostatic bitumen kettle improves mix quality, while the 20L emulsion sprayer ensures strong adhesion and waterproofing.

5.Clean & Safe Operation – The water-based dedusting system minimizes dust and smoke emissions, creating a cleaner work environment. The insulated drum reduces heat loss and maintains safe external temperatures.

With high productivity, low fuel consumption, and full recyclability, the ENUO asphalt recycler is an ideal solution for fast, sustainable, and cost-efficient asphalt repairs.